Last week I was finishing a commission for a customer. They wanted a knitted scrunchie. This isn’t a daunting task, until my row counter broke.

It started like any other project

I set up at my machine, happily zip-zipping as I passed the carriage across the bed. Until I noticed that my row counter wasn’t counting up in the tens collumn. The ones were counting up, but when the number goes from 009 to 010 it became 000. Not good. After manually checking the knobs and activation lever were functioning I determined that it was not a problem I could fix while the commission was still on my machine.

I could still work with a busted 10s counter. Manually turning the knob wouldn’t be a huge trouble, and I could still keep my progress with the 1s. Then the 1s counter stopped working, too! This problem was clearly worsening. With the row counter now completely out of commission I was counting in my mind, and manually turning the row counter to track my progress.

So much counting

1, 2, 3, 4, 5, 6, 7, 8, 9, 10. Stop. Turn row counter knob. Continue.

1, 2, 3, 4, 5, 6, 7, 8, 9, 10. Stop. Turn row counter knob. Continue.

1, 2, 3, 4, 5, 6, 7, 8, 9, 10. Stop. Turn row counter knob. Continue.

The two knitting errors that I had were not kind to my counting.

1, 2, 3, 4, 5, 6, 7, 8, 9, 10. Stop. Turn row counter knob. Continue.

1, 2, 3, 4, 5, 6, 7, 8, 9, 10. Stop. Turn row counter knob. Continue.

1, 2, 3, 4, 5, 6, 7, 8, 9, 10. Stop. Turn row counter knob. Continue.

Eventually I started counting to 20, then 30.

400 rows later…

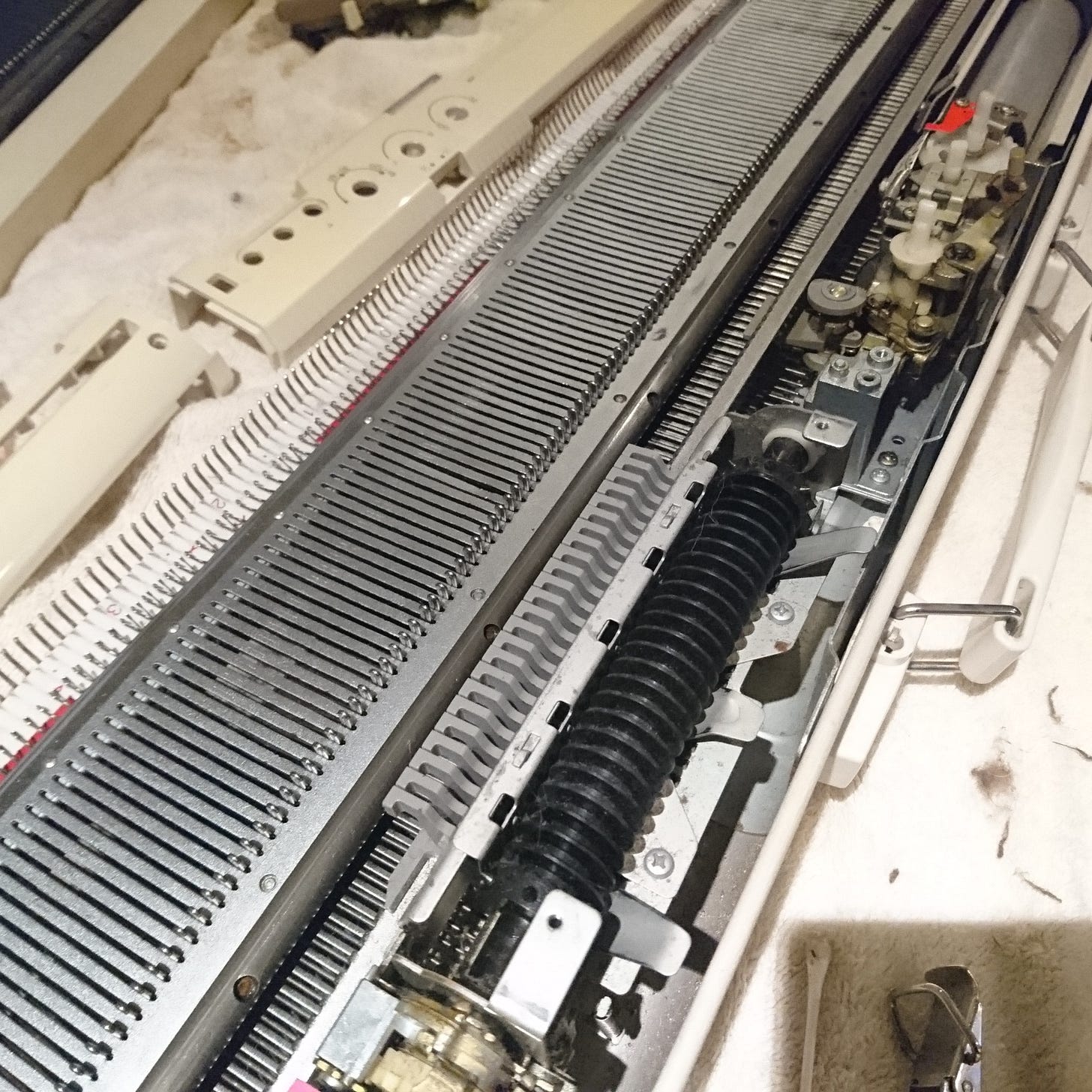

The commission is removed from the machine. Now I have to get to my row counter. It is under a plastic cover on my machine. To start, I set up a raggedy towel on my work surface to protect it from any grease or shmutz. First the grasshoppers/yarn tension unit comes off the back of the machine and are set aside. Then the ribbing bed is removed and place on the towel. After that comes the knitting bed.

With the bed containing the row counter on my towel, I have to remove the plastic covers. There are little plastic knobs and screws that come out. Each little screw is examined for unique traits so that I can remember to “put that thing back where it came from...!” They go inside of a glass beaker with the knobs.

After the plastic cover is removed I can see the row counter in full. It is a unit that is held in place by a single screw.

Examine the row counter

Once it is removed, I can see that a lever with multiple prongs is held against the gear teeth underneath each number drum. The metal prong gets moved back and forth, increasing the count. The numbers are on an angled disc with a knob on top, and a gear underneath to create the drum. The lever interacts with each drum as the 1s column is moved. There is a divet in each drum’s tooth when the number moves from 9 to 0, allowing the lever to push the next gear over and move that drum. It’s super cool and a relatively simple device.

The device stopped working because the lever is not held against the gears. Perhaps the spring has loosened, or the oil became sticky and prevented the lever from returning to the correct position.

After much investigation we discovered the issue and fixed it.

Reassemble the machine

After the row counter was reassembled I did one last test.

While I was back here I removed some dust and oiled a few other joints. It was a steady study and replace effort. Noting which screws can from each spot made the process smooth. I learned a bit about how a knitting machine works together.

If you find your row counter has stopped working, try applying oil to the joint before anything else. It might do the trick.

Did this help you understand your machine? Has your row counter ever stopped working?